When buying a stove it’s important to not only make sure you understand all of the jargon that gets thrown about when you speak to someone in a stove shop or look online at stoves, you also need to understand about the flue or chimney system that’s going to be used for your installation and why it’s being used.

We’ve created another helpful blog to help you get to grips with the terms that many installers and fitters use when it comes to your flue and chimney system. Remember to always use a flue thermometer to make sure that your stove is running at the best operating temperature!

Single Wall Flue

What is it?

- Single Wall Flue is often referred to as vitreous enamel, single skin flue or connecting flue pipe or even starter pipe. The term ‘single wall’ refers to the fact that there is only one layer of steel with no insulation.

- Single wall flue is generally made from steel and coated with enamel; this provides a smooth internal and external finish. Sometimes, however, it can be manufactured using stainless steel with no enamel coating. It is usually available in a matt black or gloss black finish but can be sprayed to match any stove with the correct high temperature paint.

When can I use it?

- Single wall flue pipe is designed to connect the top of your appliance, be it woodburning, Multifuel or even gas, to your main flue system or chimney. Your main system could be a flexible liner down an existing chimney or it could be a twin wall flue system.

What building regulations say?

- Building regulations state that you can only go up to 150mm away from the ceiling in single wall flue before moving to your main flue system. It is also not designed to be fitted through walls, ceilings or roofs, and has a larger distance to combustibles than a twin wall system. Single wall flue should be a minimum of three times the flue diameter to any combustible materials, whereas twin wall can go as close as 50-65mm depending on the system.

Twin Wall Flue

What is it?

- Twin wall flue is also known as double skin flue, or a factory made chimney. Twin wall flue pipe is manufactured from stainless steel and is made up of two steel walls, kept separate by a layer of high grade insulation.

- Twin wall is usually provided in a stainless steel finish, but is available from some suppliers with a powder coated finish in either black or ivory. A powder coated finish is used rather than spray paint as it is more durable, this finish is available due to the layer of insulation between the first and second flue walls, as the temperature on the outside is not as great as on a single skin piece.

- The layer of insulation in twin wall flue keeps the flue gases warmer and allows the flue to perform correctly and efficiently, whilst also reducing the build up of condensates within the flue system.

When can I use it?

- Twin wall flue systems are used with a stove when it is fitted into a property where there is no masonry chimney. It can run internally or externally and it achieves higher temperatures due to the layer of insulation.

- You cannot use single wall flue pipe in place of twin wall flue pipe. Single wall flue pipe is not insulated and therefore loses a lot of heat. The layer of insulation in twin wall flue keeps the flue gases warmer, allowing the flue to perform correctly and efficiently, whilst also reducing the build up of condensates within the flue system.

Termination Points:

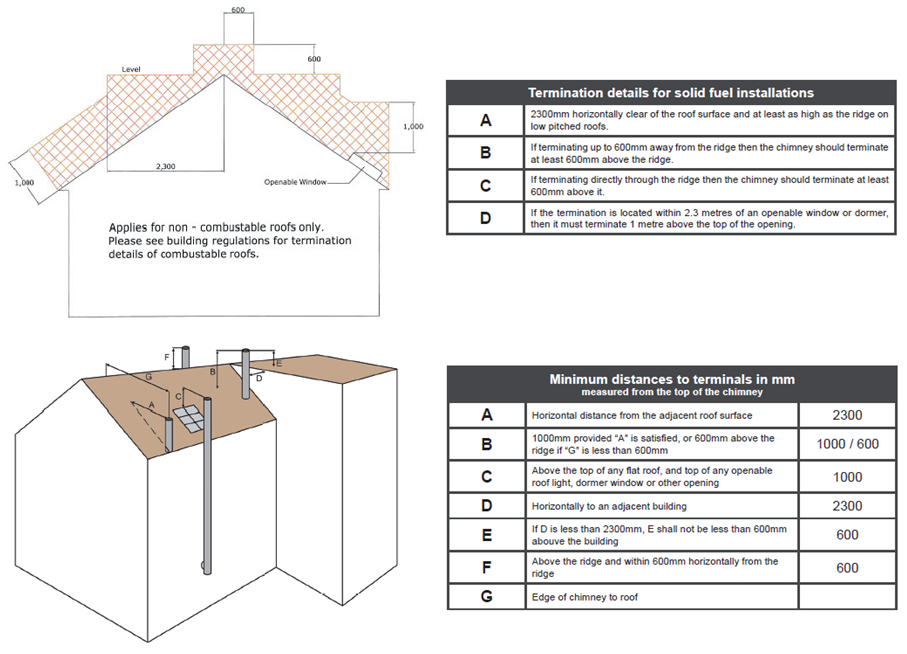

- Where the chimney passes through a pitched roof of more than 0.6m from the ridge, the horizontal distance between the roof and the chimney termination should be not less than 2.3m, unless the termination is at least 0.6m above the ridge.

- Where the discharge end of the chimney flue is within a horizontal distance of 2.3m from any adjoining structure or opening into building, the termination height must not be less than 1m above that structure or opening.

Flexible Liner

If twin wall is not an option for you and you already have a chimney in place. Lining it using a flexible liner made from double skin stainless steel is the easiest way of installing a stove. These liners are smooth on the inside and corrugated on the outside and must be installed the correct way up. A flue liner can be installed into a masonry chimney to produce a continuous and unbroken flue from the appliance to outlet. This prevents flue gasses escaping though disintegrating brickwork and provides the optimum flue diameter for the appliance.

When looking for flue liners for woodburning and Multifuel appliances you are looking for class 1 liners with an inner of either 904 or 316 grade. The difference between these two liners is the thickness of the stainless steel layers within the steel. The 316 liner is suitable for most domestic wood burning stoves, whereas, the 904 is a higher grade liner, which is thicker and more resilient than the 316 and is suitable for multifuel appliances, the use of smokeless fuels and for boiler stoves, due to the slightly higher production of acidic condensates when burning smokeless fuels and those produced whilst a stove is ‘slumbering’.

It’s always worth checking what warranty your liner has and whether your stove guarantee is affected by the type of liner or chimney system used.

Lining a chimney makes it easy to maintain and sweep, and if used with the correct fuels can last a lifetime.

Other Points to remember:

When buying flue always check that it is suitable for the purpose you have for it and that it is the correct diameter for your appliance and that it meets building regulations.

Always remember to think about how your system can be cleaned. Can you sweep through the stove? Do you need another access point for sweeping? Do you need to buy flue with a door to make sweeping easier. These are all things that need to be considered when looking at different types of flue.

Each stove provider will have a minimum draught for your stove to reach optimum efficiency and productivity – most of the time this is 12 Pascal, which you would need a minimum chimney height of 4.5 metres but ideally 7-8 metres or taller, your installer should perform a draught test to make sure the chimney is suitable for the stove that you have chosen.

If an appliance is fitted with a 125mm collar it must have a smoke exempt certification from DEFRA so that it can be fitted with a 125mm flue. If not it must go up to at least a 150mm diameter flue to comply with regulations.

There are always other systems to consider, such as a brick block twin wall flue system. Which works in much the same way as a twin wall system, and must adhere to the same guidelines, however, being a purpose built chimney means you won’t have to have a pipe going up the outside of your house.